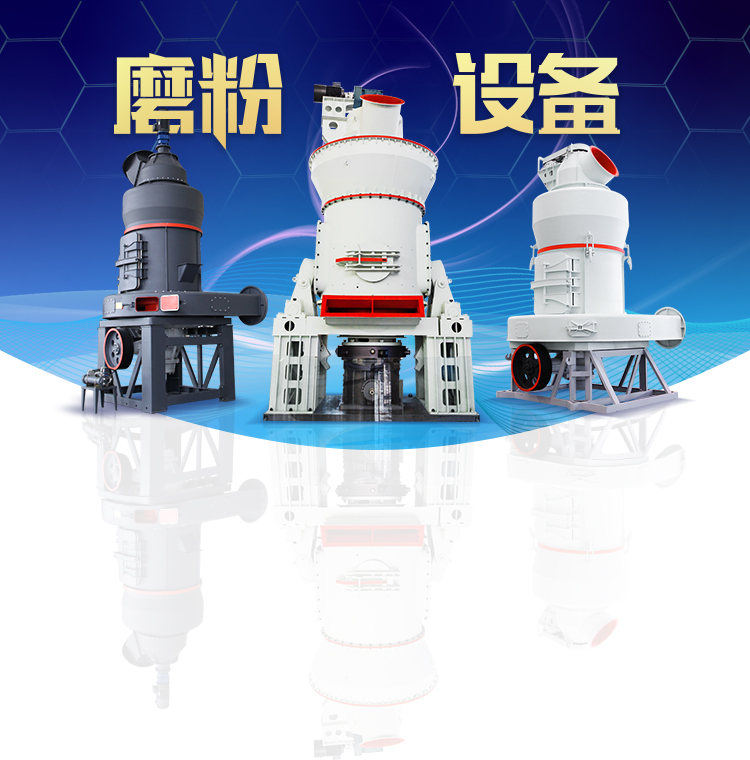

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Extraction Of Gold Plant Design

Modular Plants: Gold Processing

2023年8月29日 Modular plants for extraction and recovery of gold are customdesigned for a specific application due to the characteristics of the gold bearing ore Benefits of modular plants for gold beneficiation are: • Short construction times • Low capital costs • Easily movable2021年6月24日 For example, exploration drilling and geological analysis can infer a potentially economic gold deposit based solely on gold grades However, process factors, such as ETALLURGICAL PROCESS D PLANT ESIGN AusIMM2017年8月1日 This paper presents a method for externalising and formalising knowledge involving the selection of hydrometallurgical process flowsheets for gold extraction from ores Designing gold extraction processes: Performance study of a 2021年4月14日 Research shows that recovery in these traditional sluices yields much losses of the gold (mostly fine gold) to tailings, resulting in low/poor recovery Therefore, this project Design of a Combined Gravity Concentration and

Plant Design and Commissioning SAIMM

2011年5月29日 gold ores is simply to check their amenability to the known processes of gold recovery such as comminution, concentration, thickening, cyanidation at am bient pressure 2009年8月27日 Assuming that a gold ore has been effectively ground to ensure maximum economic liberation of gold, the circuits that will have the most effect on the successful The process design of gold leaching and carboninpulp 2024年12月5日 They involve a combination of mechanical, chemical, and physical processes to extract gold from ore A 100ton capacity facility is designed to process 100 metric tons of ore Design and Implementation of a 100Ton Capacity Gold Processing Plant2025年2月24日 Leaching and Extraction: The leaching process involves dissolving gold from the ore using a chemical solution We specialize in CarboninLeach (CIL), CarboninPulp (CIP), Gold Processing Plants Tomarok Engineering

.jpg)

Extraction of Gold, CIL Gold Processing Plant, CIL Gold

In March 2015, Xinhai took charge of African Zimbabwe Huangzhi 700tpd CIL gold processing plant, the plant is mainly quartzite gold mine, most is oxidized ore or primary ore with low The process that adopt activated carbon to adsorb and recovery gold from cyanide pulp directly without filtering gold elution plant 01 Leaching pulp preparation; 02 Cyanide leaching→activated carbon adsorption; 03 Gold Gold Elution Plant, carbon elution gold, zadra 2017年8月1日 Modelling all facets of a processing plant with a vast number of straightforward rules and deterministic equations is highly challenging, as the available data is often incomplete and fuzzy (Rintala et al, 2012, Rintala et al, 2015)Instead, the target of this study is to develop a software system that is able to give starting points for gold ore process design by helping the Designing gold extraction processes: Performance study of a 2024年10月16日 To extract gold from ore, various methods are employed, each suited to different types of ore and scales of production The primary goal of gold processing is to efficiently and economically recover gold from its host materials while minimizing environmental impact This passage will explore the most common gold processing methods used in modern mining and 5 Kinds of Gold Processing Methods Mining Pedia

Estimating process design gold extraction, leach

2018年10月23日 Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard benchscale bottle roll or agitation leach tests The application of laboratory data to process design has essentially evolved from the testing of oxide or low cyanideconsuming ores Such scaleup factors may not be 2023年5月26日 optimisation to improve gold extraction efficiencies and to reduce reagent consumption and operating plants, with the aim of providing a tool for plants which can assist in decisions regarding plant design, operation and optimisation The aim of this project was to develop and validate a dynamic model of the CIL section of a gold tailingsDynamic Modelling of a Carboninleach Gold 2016年5月3日 Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful Gold Ore Processing, Volume 15 2nd Edition2022年10月15日 Currently, the thiosulfate gold leaching operation at the Goldstrike mine, Nevada, of Barrick Gold Corp is the only largescale gold extraction plant with an alternate lixiviant (Azizitorghabeh et al, 2021) Although research on sulfurcontaining lixiviants has been the most common in gold hydrometallurgy in the past three decades, few Review A systematic review of gold extraction: Fundamentals

.jpg)

Solvent Extraction Electrowinning (SX/EW)

2015年11月9日 The SX plant was built with four parallel trains each having three extraction and two stripping mixersettlers The total flow capacity was 4,921 liters per minute (l/min) of aqueous leach solution using a 1:1 organic to aqueous 2025年1月6日 The use of resins for gold extraction was first proposed by the United States Bureau of Mines and was industrially implemented at the Muruntau deposit in Uzbekistan in July 1969, where it demonstrated high efficacy Kazmekhanobr has developed a novel ionexchange technology that incorporates a threestage cascade for sorption gold extractionFull article: Technology Development of Gold Heap Leaching plant design projects of gold extraction in harare plant design projects of gold extraction Products Solutions Contact Us About Us manufacturers of vsi stone crusher Cyanide Leach Packet The disaster in Romania at Aural Gold Plant is one 1 The cyanide process for extracting gold was an improvement over the Cyanide Leach Packet plant design projects of gold extraction monunivershamon2022年8月1日 Since the birth of cyanidation, it has been dominant in the gold extraction industry Recently, with the increasing awareness of environmental hazards and potential risks posed by the severe (PDF) A systematic review of gold extraction: Fundamentals

.jpg)

Containerised/Modular Gold desorption reCovery

2018年5月28日 extraction of gold from cyanide solutions Methods for chemically desorbing gold from loaded carbon has made it possible to apply these methods for gold recovery These procedures also allowed for the recycling of carbon for further gold recovery Today, many options are available to the plant designer and operator for desorption of gold from 2024年7月7日 Explore the rich history of gold mining and processing, delve into various extraction methods, and discover the machinery used in gold extraction plants Understand the environmental impact, modern technologies, and safety regulations that shape the industry Gain insights into the economic benefits and challenges, and anticipate future trends and The Evolution of Gold Extraction: From Ancient Times to 2015年1月1日 The extraction of rubidium from gold waste from the Mouteh processing plant in Iran by a threestep process (acid washing, followed by salt roasting and water leaching) was optimized The acid washing step for removal of impurities was found to be optimal at 85 °C and 5 h, using 5 M nitric acid Factors effecting roasting operation were then Extraction of rubidium from gold waste: Process optimization2017年11月26日 The continuous elution process is a continuous countercurrent system operating in a pressure vessel at elevated pressure and temperature in which both carbon and the eluate are simultaneously moving through each Continuous Elution for Extraction of Gold from

.jpg)

The process design of gold leaching and carbon

Semantic Scholar extracted view of "The process design of gold leaching and carboninpulp circuits" by W Stange In each alternative, the cyanide solution is sent to a SART (sulphidization, acidification, recycling and thickening) plant 2025年2月25日 Gold CIL Processing Plant Design Considerations The design of a gold ore CIL processing plant must take into account a variety of factors to ensure optimal performance and economic viability Some of the key design considerations include: 1 Ore Characteristics The mineralogy, grade, and other physical/chemical properties of the gold ore feed Gold Ore CIL Processing Plant zenithcrusher2019年12月15日 Methods for largescale extraction of gold were developed by Romans, who made long aqueducts to enable them to sluice large alluvial deposits for gold recovery The feed material for gold recovery is now hard rock ores for most of the commercial gold recovery operations 546 Plant Design Design responsibilities can be based upon total Gold and Silver Extraction SpringerLink2021年1月31日 A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a standard but reflect the nature of the ore and the design basis for a particular situationThe process design of gold leaching and carboninpulp

.jpg)

Gold Extraction from a Refractory Ore Using Calcium

2025年2月5日 Conventional leaching, the standard method for gold extraction, involves using a cyanide solution to dissolve gold from the ore However, this process is often ineffective for refractory ores due to the presence of sulfide minerals This study aims to improve the efficiency of gold extraction from refractory ores by introducing an oxidative pretreatment step using a 2015年5月1日 Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard benchscale bottle roll or agitation leach testsEstimating process design gold extraction, leach residence 2022年3月1日 A systematic review of sustainable gold extraction from raw ores using alternative leaching reagents Author links open overlay panel Rui Sousa a c, Maria João Regufe b, In 2014, at Barrick's Goldstrike plant in Nevada, USA, the first gold bar was produced using thiosulphate solution The goldbearing ore was heated as a thick slurry of A systematic review of sustainable gold extraction from raw 2016年3月2日 The gold cyanidation process has been the universal gold and silver extraction process used since its development by MacArthur and Forrest in 1889 At the CoO gold plant (Phillipines), the Process Plant Design Considerations for High Silver Gold

.jpg)

(PDF) Factors influencing the rate of gold

2011年5月1日 With the collapse of the uranium oxide yellow cake market, the uranium plant was closed in 1988 and successfully converted into a gold plant, recovering gold from repulped tailings dams12021年3月18日 This article will introduce the flow of a CIP gold processing plant: from raw gold ore to gold bar step by step The main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal How Does A CIP Gold Processing Plant Work?2024年2月3日 Platinum group metals (PGM) were separated from gold processing plant effluent using biomaterials with novel functional groups Different biomass wastes, such as wheat straw, canola meal, and wood bark nuggets were used and immobilized with dithiooxamide (DTO), ethylenediamine (EN), and primary amine (PA) to create 12 novel biosorbentsExtraction of Platinum Group Metals from Metallurgical Plant The process that adopt activated carbon to adsorb and recovery gold from cyanide pulp directly without filtering gold elution plant Desorption electrolysis system as gold extraction equipment obtains gold Leaching agitaion tank is Gold Elution Plant, carbon elution gold, zadra

.jpg)

Gold Processing Plant Design FraserLever

FraserLever undertook the EPCM component for the expansion of the existing oxide gold treatment plant on Simberi Island, including using leading edge innovation on the overall gold plant design The scope of the gold plant 2011年5月1日 Worldwide gold recovery on activated carbon grew from zero to almost 70% in twenty years from 1980 The stellar attributes of carbon gold plants led to complacency in the industry in designing and operating these plants Most CIP and CIL plants are overdesigned and operated suboptimally Optimum design criteria and operating conditions are easily Factors influencing the rate of gold cyanide leaching and adsorption 2024年6月13日 Hydrometallurgical gold recovery processes play a pivotal role in the gold mining industry, contributing to more than 90% of global gold production Among the array of techniques available, the Merrill–Crowe Advances in Hydrometallurgical Gold Recovery Download scientific diagram Gold ore extraction plant flowsheet from publication: Online Optimization of a Gold Extraction Process A phenomenological dynamic model of gold ore leaching Gold ore extraction plant flowsheet Download Scientific

Modular Plants: Gold Processing

2023年8月29日 Modular plants for extraction and recovery of gold are customdesigned for a specific application due to the characteristics of the gold bearing ore Benefits of modular plants for gold beneficiation are: • Short construction times • Low capital costs • Easily movable2021年6月24日 For example, exploration drilling and geological analysis can infer a potentially economic gold deposit based solely on gold grades However, process factors, such as refractoriness leading to low recovery or gangue components leading to high reagent consumption, can complicate the processing of the ore and may render the deposit uneconomicETALLURGICAL PROCESS D PLANT ESIGN AusIMM2017年8月1日 This paper presents a method for externalising and formalising knowledge involving the selection of hydrometallurgical process flowsheets for gold extraction from ores A casebased reasoning (CBR) system was built using an open source software myCBR 30Designing gold extraction processes: Performance study of a 2021年4月14日 Research shows that recovery in these traditional sluices yields much losses of the gold (mostly fine gold) to tailings, resulting in low/poor recovery Therefore, this project seeks to design a combined gravity concentration and leaching plant to improve gold recovery in the smallscale minesDesign of a Combined Gravity Concentration and

Plant Design and Commissioning SAIMM

2011年5月29日 gold ores is simply to check their amenability to the known processes of gold recovery such as comminution, concentration, thickening, cyanidation at am bient pressure and temperature, liquid! solid separation, and recovery of gold2009年8月27日 Assuming that a gold ore has been effectively ground to ensure maximum economic liberation of gold, the circuits that will have the most effect on the successful operation of a gold plant will be that of the leaching and carboninpulp circuit (CIP)The process design of gold leaching and carboninpulp 2024年12月5日 They involve a combination of mechanical, chemical, and physical processes to extract gold from ore A 100ton capacity facility is designed to process 100 metric tons of ore per day, making it suitable for midsized mining operations Key objectives include: Maximizing recovery rates Ensuring environmental compliance Reducing operational costsDesign and Implementation of a 100Ton Capacity Gold Processing Plant2025年2月24日 Leaching and Extraction: The leaching process involves dissolving gold from the ore using a chemical solution We specialize in CarboninLeach (CIL), CarboninPulp (CIP), and heap leaching systems, optimizing each to match the specific characteristics of the oreGold Processing Plants Tomarok Engineering

.jpg)

Extraction of Gold, CIL Gold Processing Plant, CIL Gold

In March 2015, Xinhai took charge of African Zimbabwe Huangzhi 700tpd CIL gold processing plant, the plant is mainly quartzite gold mine, most is oxidized ore or primary ore with low sulfur ore, so Xinhai chose gravity separation + allsliming CIL process, which achieved efficient extraction of gold, save 15% costThe process that adopt activated carbon to adsorb and recovery gold from cyanide pulp directly without filtering gold elution plant 01 Leaching pulp preparation; 02 Cyanide leaching→activated carbon adsorption; 03 Gold charcoal desorption; 04 Obtain gold mud through electric shock; 05 Gold charcoal recycling; 06 Leaching pulp processGold Elution Plant, carbon elution gold, zadra gold elution

石灰石厂财务

--广西重钙悬辊磨生产线

--石头代表什么寓意

--渣场制度

--萤石矿石磨粉机生产线的萤

--强力粉碎机强力粉碎机强力粉碎机

--赤峰35大型粉碎机

--矿石制粉厂应急救援预案

--炼钢厂用钢渣磨立磨治疗仪价格

--生石灰石灰石粉碎机2LSY915性能

--陶瓷对滚机矿石磨粉机

--湛江雷蒙磨和球磨机加工厂

--混凝土生产调度年终总结

--1吨生石灰需要多少水消解

--2p325目石灰石粉生产线系列矿石磨粉机

--水渣活性系数

--冲击碳酸钙粉碎站产量30TH

--设备折全新可以分红吗

--小型大型球磨机

--粉磨生产线需要多少润滑油

--非法采矿罪案例非法采矿罪案例非法采矿罪案例

--甘肃定西那个农机公司销售磨粉机

--贵州省哪里方解石多

--方解石矿爆破一吨单价多少

--开办矿产品加工厂

--江西鹰潭市方解石粉生产设备厂家直销

--磨粉机喂料口

--分级式立式辊磨机立磨设备报价厂家

--白云石磨粉生产线价格

--雷蒙磨含水

--