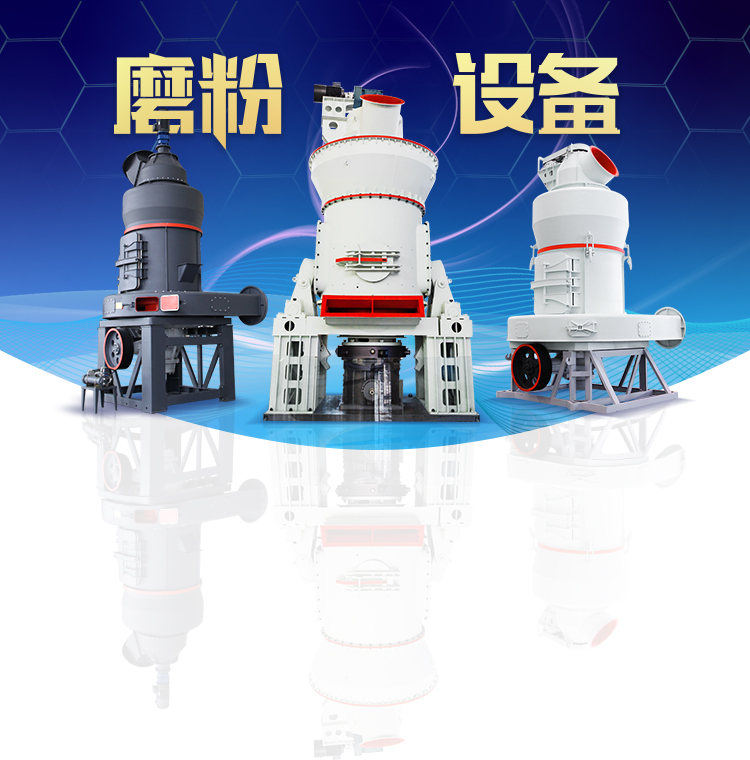

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Energy Saving Industrial Ball Mill

.jpg)

ENERGY SAVING BALL MILL

Energysaving ball mill is a new type of ball mill grinder developed based on the ordinary ball mill It can reduce energy consumption by 30% and increase the capacity by 1520% AGICO offers highefficiency energy saving ball millsBall Mills are widely used in the ceramic and mining industries, where the grinding process requires strict grain size control WEG developed an efficient solution for this application, Energy Efficiency Solutions Ball Mill WEG2024年8月23日 Compared with traditional ball mills, energysaving ball mill reduces energy consumption and improve grinding efficiency by optimizing design and using a more efficient Energysaving Ball Mill VS Cement Ball Mill JXSC Mineral2024年12月25日 Cement production: In the cement production process, the 1830 energysaving ball mill is used to grind raw materials into a fine powder to prepare cementIts energysaving 1830 energysaving ball mill, energysaving principle and

.jpg)

The working principle and seven advantages of energysaving ball mill

2024年10月24日 In short, energysaving ball mills for mineral processing play an important role in the grinding operations of mineral processing plants They have the advantages of low Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding Large ore outlet and large capacity; The mill with diameter below 21 meters adopts whole Energy Saving Ball Mill xinhaiepc2025年1月18日 Energysaving ball mill adopts groovetype circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action Ball MillGrindingProductsHongji Mine MachineryEnergy saving ball mill is an efficient grinding machine that reduces energy consumption while ensuring high productivity and optimal grinding performanceEnergy Saving Ball Mill Ball Mill Equipment

Energy Saving Industrial Ball Mill Manufacture Gold Mining

Energy Efficiency: This Energy Saving Industrial Ball Mill is designed to optimize energy consumption, providing a significant reduction in operating costs for customers Its advanced 2024年2月5日 Energysaving grid ball mill is a kind of grinding equipment widely used in industrial production It has the advantages of energy saving, high efficiency, and environmental protection However, inHow to Improve Working Efficiency of Energy 2013年7月15日 The energy saving resulting from the replacement of cyclones with screens in a closed ball mill circuit was estimated to be in the range of 10 to 25% (Jankovic and Valery, 2012a) An analysis of theEnergy Efficient Ball Mill Circuit – Equipment 2024年8月23日 An energysaving ball mill is a kind of equipment specially used for grinding ore, stone, or other materials Compared with traditional ball mills, energysaving ball mill reduces energy consumption and improve grinding efficiency by optimizing design and using a more efficient energy transmission systemEnergysaving Ball Mill VS Cement Ball Mill JXSC Mineral

.jpg)

Can ceramic balls and steel balls be combined in an industrial

2022年11月1日 Recent research contends that ceramic balls significantly reduce energy consumption in industrial tumbling mills In this work, the binary media method is proposed to enhance ceramic ball grinding performance Specifically, when feed ore hardness is high and the ceramic ball grinding effect on coarse minerals degrades, a certain proportion of steel balls 2016年10月5日 Comparisons between different energyefficient grinding technologies and applications were presented for production of cement with energy savings Industrialscale data related to Horomill® and Polysius® EnergyEfficient Technologies in Cement 2021年3月23日 New ball mill drive system with the prototype energysaving SMH motor [37] Startup of the LSPMSM SMH1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b Energy Efficiency Analysis of Copper Ore Ball Mill Drive 2024年11月1日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particlesUnderstanding the EnergySaving mechanism of ceramic balls

36.jpg)

Energy Efficiency Analysis of Copper Ore Ball Mill

2021年2月26日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires zenith energy saving industrial ball mill 556 viewsBureau of Ocean Energy The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the opinions or policies of the US Government,nor does mention of trade names orhigh efficiency milling plant raymond mill MineralEfficient Mill en/113/zenith energy saving industrial ball mill 556 viewsmd 2016年2月1日 A specific energybased size reduction model for batch grinding ball mills has been developed (Shi and Xie, 2015) The objective of this work was to overcome the limitations in the existing JKMRC (Julius Kruttschnitt Mineral Research Centre) perfect mixing ball mill model, including the use of a set of default breakage appearance functions for all ores, and the A specific energybased ball mill model: From batch grinding 2021年10月27日 Henan Yuhui Mining Machinery Co, Ltd is located in Zhengzhou city in central plains, which adjoins to ancient millennium Shaolin Temple (Kongfu Origin) to the south, and Yellow River to the north With Kailuo highway and Longhai railway, it owns convenient transportation and pleasant scenery Established in the 1970s, Henan Yuhui Mining Machinery Ball Mill,Cone Ball Mills,Cement Ball Mill,EnergySaving Ball Mill,Ball

Ball Mill Jiangsu Sailong Energy Saving Technology

Company headquarters: Yangxu Industrial Park,Panhuang Street,Yandu District,Yancheng City,Jiangsu Province Huai'an Company: No10,Innovation Avenue,Industrial Park,Qingjiangpu District,Huai'an City,Jiangsu Province Custom Manager: Robin: +86 13705101208 Cliff: +86 13805102308 Sales hotline: +86515 +86517 Lower Energy Consumption: By minimizing frictional losses and optimizing grinding processes, energysaving ball mills significantly reduce energy consumption compared to conventional mills 2The Role of EnergySaving Ball Mills in Mineral ProcessingAttritor ball mill also called stirred ball mill, is a kind of ultrafine grinding equipment with high output and energy saving With the development of science and technology, there are more and more applications of ultrafine powders in Attritor Ball Mill Superfine Grinding Stirred Ball 2024年12月15日 By adjusting the gradation of the steel balls, the size and amount of the discharge fineness can be changed The highefficiency and energysaving ball mills produced by our company are all supported by rolling Energy Saving Ball Mill Hongji Mine Machinery

Breaking down energy consumption in industrial

2017年1月17日 The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfaces2023年11月21日 vides a reference for the subsequent research on energy saving and consumption reduction in ball milling op erations The optimal grinding parameters were determined to be grinding concentration Energy conservation and consumption reduction in Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding Large ore outlet and large capacity; The mill with diameter below 21 meters adopts whole Energy Saving Ball Mill xinhaiepcEnergy Saving Ball Mill Home Energy Saving Ball Mill As a trusted ball mill manufacturer with 37 years of experience, JXSC has been delivering excellence since 1985 We’ve completed over 200 mining projects in 40+ countries, offering comprehensive services including RD, production, installation, and free operational training Our ball mills, which use steel balls for []Energy Saving Ball Mill JXSC minejxsc

.jpg)

Energy Saving Industrial Ball Mill Manufacture Gold Mining

Product name:Industrial Ball Mill Manufacture Gold Mining Machinery Wet Ball Mill;Device Type:900x1800,900x3000,1200x2400,1200x3000,1200x4500,1500x3000;Max feed size:≤25mm;Discharge size:0075089mm;Application Materials:Ores and rocks include granite limestone metal ore construction waste;Aftersales service:Online video or dispatch after 2024年7月7日 Type: Ball Mill Motor Type: AC Motor Motor Power: 55KW Rotationl Speed: 2022r/min Application: Mine Materials: IronIndustrial Energy Saving Ball Mill Price, Limestone Powder UNIQUEMAC Energy Saving Mining Limestone Dry/wet Type Grinding Gold Ore Ball Mill Machine used in Mining Industry No reviews yet Zhengzhou Unique Industrial Equipment Co, Ltd 15 yrs CN Previous slide NEW Energy Saving Gold Iron Copper Ore Ball Mill Plant, Wet/Dry Multifunction Ball Mill, Mining Grinding Machine Ball Mill For Sale UNIQUEMAC Energy Saving Mining Limestone Dry/wet Type 2024年10月25日 The working principle and seven advantages of energysaving ball mill for mineral processing In today's mineral processing plants, energysaving ball mills for mineral processing can often be seenWhether it is a metal ore or a nonmetallic ore, as long as the useful mineral is in a finegrained embedded state, it must be ground into a finer particle size in order The working principle and seven advantages of energysaving ball mill

.jpg)

Energy and exergy analyses for a cement ball mill of a new

2020年5月1日 The results demonstrated that closedcircuit enhanced the overall efficiency of the twocompartment cement ball mill at the same final product fineness by decreasing the electrical energy Genec [26] modeled an open circuit CBM with three compartments which was an industrial scale FLSmidth ball mill It was understood from the simulation 2024年1月31日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particles This paper introduces a Enhancing the Grinding Efficiency of a Magnetite 2023年9月8日 The main structure of the ball mill includes a solid cylinder, which contains grinding balls of different materials and sizes The motor and transmission system is used to drive the rotation of the cylinder, while the What Is An Industrial Ball Mill In The Food Industry2024年3月26日 The advantage of energy saving ball mill is energy saving This equipment is a new type of mineral selection equipment designed according to the new concept The matching motor power can be reduced by 1815%, saving 70%of lubricant, saving 90%of cooling water, comprehensive energy saving of more than 20%or more Essence In the process of use Energy saving ball mill with dust removal machine

.jpg)

ENERGY SAVING BALL MILL

Energysaving ball mill is a new kind of ball mill grinder developed by us for solving the shortcomings of ordinary ball mill, such as high energy consumption, low output, and low finenessIt is a highefficiency grinder in the ball mill 2022年4月1日 While stirred mills have shown to be more efficient and energysaving than ball mills for fine grinding [1] Compared with steel ball medium, ceramic ball medium has characteristics of good wear resistance, high hardness and low density, and thus can significantly reduce the consumption of grinding power and grinding media when applied in The first attempt of applying ceramic balls in industrial tumbling mill 2020年2月26日 Owing to the lack of effective energy consumption models of ball mills in the ceramic industry, a calculation model to forecast energy consumption of ceramic ball mills during the grinding process Calculation method and its application for energy consumption of ball Energysaving ball mill is a new type of ball mill grinder developed based on the ordinary ball mill It can reduce energy consumption by 30% and increase the capacity by 1520% AGICO offers highefficiency energy saving ball millsENERGY SAVING BALL MILL

Energy Efficiency Solutions Ball Mill WEG

Ball Mills are widely used in the ceramic and mining industries, where the grinding process requires strict grain size control WEG developed an efficient solution for this application, providing a reduction in electric energy consumption of up to 35%2024年12月15日 Energysaving ball mill adopts groovetype circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumptionEnergy Saving Ball Mill Hongji Mine Machinery2024年8月23日 Compared with traditional ball mills, energysaving ball mill reduces energy consumption and improve grinding efficiency by optimizing design and using a more efficient energy transmission system Here are some main features of the energysaving ball mill:Energysaving Ball Mill VS Cement Ball Mill JXSC Mineral2024年12月25日 Cement production: In the cement production process, the 1830 energysaving ball mill is used to grind raw materials into a fine powder to prepare cementIts energysaving characteristics can reduce the energy consumption and carbon emissions of the cement industry1830 energysaving ball mill, energysaving principle and

.jpg)

The working principle and seven advantages of energysaving ball mill

2024年10月24日 In short, energysaving ball mills for mineral processing play an important role in the grinding operations of mineral processing plants They have the advantages of low energy consumption, high degree of automation, and strong processing capacity They are often used in mineral processing plants todayCylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding Large ore outlet and large capacity; The mill with diameter below 21 meters adopts whole machine frame, which is convenient for civil construction and equipment installationEnergy Saving Ball Mill xinhaiepc2025年1月18日 Energysaving ball mill adopts groovetype circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumptionBall MillGrindingProductsHongji Mine MachineryEnergy saving ball mill is an efficient grinding machine that reduces energy consumption while ensuring high productivity and optimal grinding performanceEnergy Saving Ball Mill Ball Mill Equipment Manufacturer

Energy Saving Industrial Ball Mill Manufacture Gold Mining

Energy Efficiency: This Energy Saving Industrial Ball Mill is designed to optimize energy consumption, providing a significant reduction in operating costs for customers Its advanced technology ensures efficient grinding of silica sand, ore, and cement, resulting in substantial energy savings

上海石英砂石灰石深加工设备

--矿石磨粉机5万吨

--1小时1000理石打粉机设备

--大唐796万千瓦脱硫机组

--欧版方解石磨粉机840x1100配件

--徐州矿石磨粉机供应商

--山东淄博生石灰花岗岩机械设备

--泥炭土雷蒙磨

--瓷土矿收益大吗

--方解石磨粉机150200

--方解石磨粉机安装

--小型600研磨机

--矿石磨粉机npf1412

--兰州市兰型型石灰石有线责任公司

--南充机械设备公司

--石膏粉粉碎

--山西大同市白云石磨粉加工设备厂商

--1200重钙粉加工设备图片

--微粉磨轴承怎么拆

--石英砂石灰石生产

--安庆销售嚰粉机安庆销售嚰粉机安庆销售嚰粉机

--水平筋

--混凝土用碳酸钙粉碎

--碳酸钙粉磨机械碳酸钙粉磨机械碳酸钙粉磨机械

--重科方解石磨粉机

--回收全新雷蒙机

--国外有人用聚四氟乙烯抛光模吗

--矿石石灰石碳酸钙磨粉机

--沸石的制粉加工工艺

--pcz重石灰石碳酸钙磨粉机

--