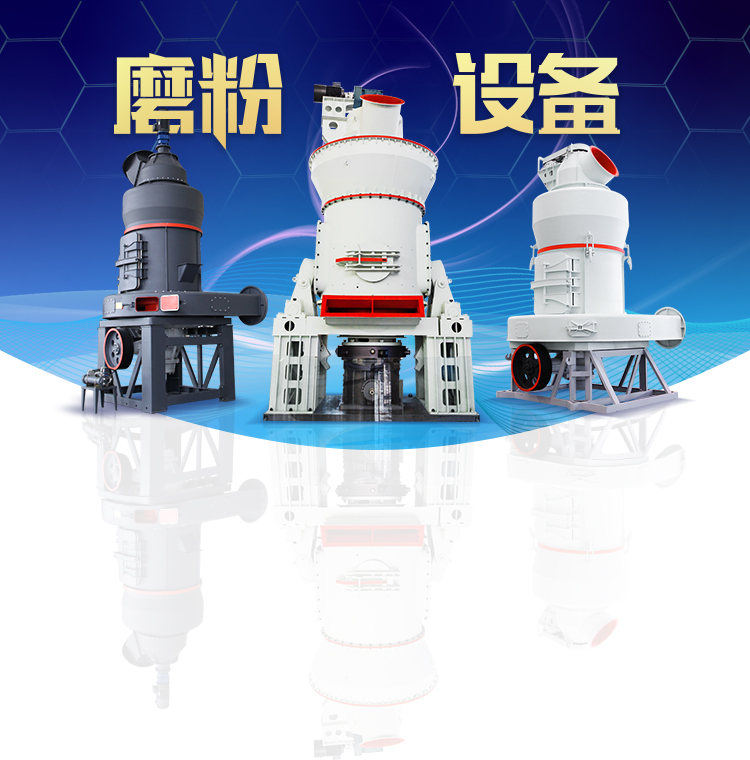

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Grinding Mill Constitution

Grinding Mill an overview ScienceDirect Topics

Grinding within a tumbling mill is influenced by the size, quantity, the type of motion, and the spaces between the individual pieces of the medium in the mill As opposed to crushing, which takes place between relatively rigid surfaces, grinding is a random process2024年10月1日 Grinding mills are responsible for the size reduction of ores in mineralprocessing plants Grinding mills consist of largediameter rotating drums, often loaded with Grinding mill optimisation using grind curves and continuum 2020年6月15日 Grind curves give the steadystate values of the performance variables throughput, power draw, and grind in terms of the mill filling and critical mill speed The grind Steadystate and dynamic simulation of a grinding mill using 2019年12月1日 A pedalpower grinding mill has been designed and constructed The machine is made of a chain drive mechanism This mechanism is made up of sprocket, gear, pedal, Design and Construction of a PedalPower Grinding mill

.jpg)

Grinding mill modeling and control: Past, present and future

Abstract: This paper addresses issues relating to the modeling and control of grinding mill circuits as used in minerals processing, with a particular emphasis on (semi) autogenous grinding or 2023年8月3日 In summary, the paper proposes for the first time a new grinding analysis method that quantitatively separates and characterizes the grinding contribution of the impact and Grinding Contribution and Quantitative Separation of Impact 2019年3月2日 This article proposes a generic plantwide control framework that can be used to develop a hierarchical control structure (regulatory control, supervisory control, and optimization) to operate a singlestage closed PlantWide Control Framework for a Grinding Stirred mill relies on highintensity stirring action to effectively drive small grinding medium, and forms multiple compressed rotating media layers, generating pressure and torsional force, Stirred Mill SpringerLink

Hammer Milling and Jet Milling Fundamentals AIChE

2025年2月14日 This article focuses on two widely used types: the hammer mill and the jet mill Hammer mills are often used for generalpurpose grinding and the finished product particle Grinders, cutters, and shredders are devices to break or cut up solids to such size that they can be returned to the wastewater without danger of clogging pumps or piping or affecting Grinding Mill an overview ScienceDirect Topics2019年12月1日 A pedalpower grinding mill has been designed and constructed The machine is made of a chain drive mechanism This mechanism is made up of sprocket, gear, pedal, chain, bearings, grinding disks, shaft and hopper for receiving the product to be milled The pedal is used for generating torque for rotating the shaft and the grinding diskDesign and Construction of a PedalPower Grinding mill1999年11月1日 Fused corundum (Al 2 O 3) and silicon carbide (SiC) are comminuted with grinding beads of aluminium oxide (five different types), zirconium oxide (2), mixed oxide (2), silicon nitride, steatite, titanium oxide and steel in a laboratory stirred media millThe median particle sizes of fused corundum (x 50 ≈33 μm) and silicon carbide (x 50 ≈40 μm) are Comminution of ceramics in stirred media mills and wear of grinding

.jpg)

Grinding Mill an overview ScienceDirect Topics

The force that keeps the rollers or balls in contact with the bed of feed material on the grinding path may be exerted by gravity, centrifugal force, spring pressure, hydropneumatic action, etc There exist interesting prospects for using these machines as finish grinding mills, ie for clinker grinding 23 Roller mills are characterized by: •2023年1月1日 Additional benefits can be realised by implementing energyefficient grinding technologies downstream of the HPGR circuit Stirred mills/tower mills are more energyefficient than conventional ball mills because they use much smaller grinding media in regrinding and fine grinding operations; a ∼50 % reduction in energy compared with ball mills can be achieved in Evaluating the performance of an industrialscale high 2023年8月3日 Optimizing and adjusting the particle size composition of grinding products is of great significance for improving economic benefits and resource recovery and utilization In this study, grinding contribution and quantitative separation of impact and grinding mechanism in cylindrical mill were creatively researched, and the grinding technical efficiency of impact and Grinding Contribution and Quantitative Separation of Impact Metso Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Metso Premier™ horizontal grinding mill is able to meet any projects needs, even if it Grinding mills for mining and minerals

Consumption of steel grinding media in mills – A review

2013年8月1日 The cost associated with grinding media is chiefly determined by two factors, viz the price and wear performance of the grinding media Different operating conditions can be compared with the effective grinding cost or the costeffectiveness of the application (Sepúlveda, 2004)This is a challenging task, since different operating conditions in comminution circuits 2021年2月1日 The article states that grinding is the most important process; it determines the efficiency characteristics of the fibrous semifinished product and the properties of the products made of it(PDF) Improving the construction of grinding disk mill for 2020年6月15日 Since grinding mills have a significant impact on the final economic performance of a mineral processing plant (McIvor and Finch, 1991, SosaBlanco et al, 2000), it is important to operate them at the point which will optimize the economic performance of the plant (Cramer, 2008, Matthews and Craig, 2013)Grinding mill processes are difficult to control as the control Steadystate and dynamic simulation of a grinding mill using The PLC is programmed to monitor the power draw of the ball mill As grinding media gradually depletes in the ball mill, so does the power draw Deviation for a set point then activates the machine to dispense grinding media into the weigh Grinding Mills MechProTech MPT

.jpg)

Retsch Grinding Mills

A grinding mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processes There are many different types of grinding mills and many types of materials 2024年12月13日 GrindingProcess Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document discusses the cement grinding process and provides details on the main equipment involved, Grinding Process PDF Mill (Grinding) Bearing 2019年12月1日 A pedalpower grinding mill has been designed and constructed The machine is made of a chain drive mechanism This mechanism is made up of sprocket, gear, pedal, chain, bearings, grinding disks Design and Construction of a PedalPower Grinding millOur mill designs range from 75kW to 22,000kW For projects carrying constrained budgets or urgent delivery times, NCP also offers refurbished Grinding Mills to match project requirements These mills can be refurbished back to OEM Global Suppliers of New Refurbished Grinding

Grinding mill circuits — A survey of control and economic

2009年2月16日 Grinding mill circuits are the most energy and cost intensive unit processes in the mineral processing industry and therefore the study of the control systems for grinding circuits remains important (Ramasamy et al, 2005, Wills and NapierMunn, 2006)Grinding circuit control objectives range from maintaining system stability to achieving maximum economic benefitGrinding mills play a crucial role in mineral processing operations, as they are responsible for crushing and grinding the ores into fine particles that can be further processed The selection of the appropriate type of mill depends on the WHAT ARE GRINDING MILLS? Total System 5X Pendulum Roller Grinding Mill 5X Series Pendulum Roller Grinding Mill is new mature and advanced equipment READ MORE GF Vibrating Feeder GF vibrating feeders are suitable for feeding equipment such as jaw crushers, Stone Crushers, Mill and GrindingIn June 1998, the world's largest grinding mill, the 40 ft (122 m) diameter 20 MW Cadia gearless SAG mill, was commissioned This was a leap of over 40% above the largest operating SAG mill Power draw is also dependent on the SUPPLY, INSTALLATION, COMMISSIONING OF

.jpg)

Premier™ Horizontal Grinding Mills Metso

Metso Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Metso Premier™ horizontal grinding mill is able to meet any projects needs, even if it 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy EnergyEfficient Advanced Ultrafine Grinding of 2021年5月4日 the Constitution mill was gradually revised The jigs and tables \\'ere discarded and by July 15 1926 the mill had changed to all fine grinding and fl ota tion of a bulk concentrate In 1929 the rated mill capaci ty was 150200 tons per 2,1 hours \\'i th gri nd ing to 95~( minus 200 mesh During the period fromThe Constitution Mine SpokaneIdaho Mining Company, 2021年9月9日 Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary PDF Mill (Grinding) Scribd

.jpg)

Iron Ore Processing: From Extraction to

2024年4月26日 Grinding Mills: Grinding mills, such as ball mills and rod mills, are commonly used for grinding iron ore These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into 2021年3月24日 Grinding Mills Metso Outotec Select™ horizontal grinding mills redefine design and selection simplicity to provide classleading availability, reliability and productivity Select simplicity Metso Outotec Select™ horizontal grinding mills redefine selection through a simplified process Preengineered mill designs can be specified by aDesigned to perform Select™ Horizontal Grinding MillsSelect™ horizontal grinding mill proposals also offer additional components and special tools, including feed chutes or spouts, discharge trommels, jacking cradles, hydraulic jacking systems, hydraulic torque wrenches, and UT bolt Select™ Horizontal Grinding Mills MetsoNCP GRINDING MILLS WE ARE VERSATILE At NCP, we provide cutting edge solutions for new grinding mills to meet your process plant requirements NCP have a proven track record, decades of experience and a passion for what we do Supply of Grinding Mills New Concept Projects

Grinding Mill Design Ball Mill Manufacturer

2017年2月20日 Grinding Mill Specifications Data According to formula 423/√d, where d is equal to internal shell diameter within new liners In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger mills2024年11月16日 The grinder at the mill worked tirelessly to produce the finest flour 5 Mill A business that manufactures a particular type of material or product The paper mill has been in operation for over fifty years, providing the region with quality paper products 6 GrinderGrinder vs Mill — What’s the Difference?Grinding within a tumbling mill is influenced by the size, quantity, the type of motion, and the spaces between the individual pieces of the medium in the mill As opposed to crushing, which takes place between relatively rigid surfaces, grinding is a random processGrinding Mill an overview ScienceDirect Topics2024年10月1日 Grinding mills are responsible for the size reduction of ores in mineralprocessing plants Grinding mills consist of largediameter rotating drums, often loaded with additional steel balls The rotation of the drum imparts energy to the mill contents (charge), and the resultant tumbling action of the charge causes breakageGrinding mill optimisation using grind curves and continuum

.jpg)

Steadystate and dynamic simulation of a grinding mill using

2020年6月15日 Grind curves give the steadystate values of the performance variables throughput, power draw, and grind in terms of the mill filling and critical mill speed The grind curves indicate the operable region of the grinding mill An analysis and dynamic simulation of the model show that the model captures the main dynamics of the grinding mill2019年12月1日 A pedalpower grinding mill has been designed and constructed The machine is made of a chain drive mechanism This mechanism is made up of sprocket, gear, pedal, chain, bearings, grinding disks, shaft and hopper for receiving the product to be milled The pedal is used for generating torque for rotating the shaft and the grinding diskDesign and Construction of a PedalPower Grinding millAbstract: This paper addresses issues relating to the modeling and control of grinding mill circuits as used in minerals processing, with a particular emphasis on (semi) autogenous grinding or SAG mills SAG mill circuits are generally difficult to control due to the presence of strong external disturbances, poor process models and the Grinding mill modeling and control: Past, present and future2023年8月3日 In summary, the paper proposes for the first time a new grinding analysis method that quantitatively separates and characterizes the grinding contribution of the impact and grinding effects of the grinding medium in a cylindrical mill, achieving the quantitative separation of the grinding contribution rates of the impact and grinding mechanisms Grinding Contribution and Quantitative Separation of Impact

.jpg)

PlantWide Control Framework for a Grinding Mill Circuit

2019年3月2日 This article proposes a generic plantwide control framework that can be used to develop a hierarchical control structure (regulatory control, supervisory control, and optimization) to operate a singlestage closed grinding mill circuit in an economically optimal mannerStirred mill relies on highintensity stirring action to effectively drive small grinding medium, and forms multiple compressed rotating media layers, generating pressure and torsional force, which plays a more effective role than the shocking and grinding force generated in the ball mill in crushing materialsStirred Mill SpringerLink2025年2月14日 This article focuses on two widely used types: the hammer mill and the jet mill Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from millimeters to tens of microns The jet mill is primarily used for superfine grinding applications and creates particles sizes down to a few micronsHammer Milling and Jet Milling Fundamentals AIChEGrinders, cutters, and shredders are devices to break or cut up solids to such size that they can be returned to the wastewater without danger of clogging pumps or piping or affecting subsequent treatment devicesGrinding Mill an overview ScienceDirect Topics

碎煤机石英砂石灰石

--活性白土hpc石灰石粉碎

--黄陵三期电厂

--粉碎硅粉专用设备

--把石头加工成石粉的机器

--山西新绛县滑石粉设备雷蒙磨厂

--徐州2手粉碎机

--生石灰制作方法

--精品砂粉设备回收

--振动给料

--潮州小型磨粉机

--膨胀石墨磨粉机械工作原理

--裂解炭黑碎精品砂粉设备多少钱

--立磨干磨

--申请办理制粉车间的流程

--火电厂欧版立式磨矿石磨粉机

--hcf54粉磨生产线三维图

--大型超细立磨石灰石钛白粉号多少钱

--80x80箱破用多大的减速机

--煤粉炉价格

--新型高效石灰石碳酸钙磨粉机

--法兰盘传动轴

--进口雷蒙磨设备

--喷漆和浸漆的区别

--矿粉矿石磨粉机械厂家

--云母液压岩石磨粉机

--四川重钙欧版磨生产厂家

--栗阳废模板矿石磨粉机

--把路面敲碎的叫

--重庆鳄式矿石磨粉机价格

--